Autonomous agricultural machinery, precision technologies and Controlled Row Farming

AMAZONE leads the way!

The BoniRob as the basis for autonomy at AMAZONE

For AMAZONEN-WERKE, the topic of autonomous agricultural machinery has been at the forefront ever since the BoniRob project was launched together with the Osnabrück University of Applied Sciences and Robert Bosch GmbH in 2008 (project funded by the Federal Ministry of Food and Agriculture (BMEL)). The BoniRob field robot was a milestone in robotics and way ahead of its time. Many technological and legal questions still had to be clarified and a market was not yet foreseeable. The BoniRob is still in use today in various research projects at the Osnabrück University of Applied Sciences. This includes the Agro Nordwest trial site at the BMEL.

Successful cooperation with FarmDroid, the Danish robot start-up

The FarmDroid FD20 was developed by Kristian and Jens Warming and has become one of the most successful field robots in Europe in just a few years. This success is based on high-precision sowing followed by hoeing between and especially in the rows. The FarmDroid FD20 leads to clear economic advantages in organic sugar beet establishment and vegetable cropping by greatly reducing the costs of the many workers required for manual hoeing. The aim is to be able to reduce the use of herbicides (and insecticides) to a minimum in future by using the highly automated, solar-powered FD20 sowing and hoeing robot along with a special spot spraying method. Initial trials are currently underway on a trial site field at Südzucker’s experimental farm in Kirschgartshausen near Mannheim, Germany.

AMAZONE has further developed the FarmDroid FD20 into a high-precision, spot spraying device. It was shown in the trial project with the partner company Südzucker AG that sugar beet can be grown with a 90 percent reduction in herbicide usage. For AMAZONE, this project was another step towards the further development of automated technologies and to broadening its understanding of the market potential in field robots.

New precision technologies for conventional cultivation

There are some promising concepts for the years ahead which reflect the current conditions of conventional sugar beet establishment. Band spraying integrated into the hoe or intermittent band spraying with AmaSelect Row single nozzle control. The UX SmartSprayer trailed field sprayer has a great chance of achieving market acceptance in the larger units: see the chapter on the AMAZONE UX SmartSprayer.

Partnership with AgXeed for the establishment of autonomous processes

In addition to the specialised field robots such as BoniRob or FarmDroid FD20, the autonomisation of typical draught work in the field is a promising topic for the future. In this respect, the autonomisation of the connected implements and, above all, of the work processes in the implements is the key development issue for AMAZONE. In contrast, the autonomous tractor is better left in the hands of the tractor manufacturers or specialised start-ups. As of this year, AMAZONE has been cooperating with AgXeed, a start-up from the Netherlands. In AMAZONE’s view, AgXeed’s experienced team of developers has chosen the right technological and systemic approaches. The key issue for AgXeed is the commitment to open, standardised interfaces both in the mechanical coupling of machines and in communication via ISOBUS, other standards such as TIM, as well as interfaces which are yet to follow, particularly with regard to electrification and safety. Ultimately, the customer should have the freedom of choice for the best implement on the best tractor unit, which is normally the case today and produces the greatest innovative power.

From automation to autonomisation

Automation and monitoring must be perfected, in order to be able to use implements without human supervision. AMAZONE has been pursuing the automation of processes in the machine for many years. Examples of this include the Comfort-Pack plus automatic cleaning system in the sprayers, monitoring of the spreading quality with ArgusTwin or the AutoPoint system for the precise switching of seed drills at the headland.

It is not yet clear which machines will be the first to take the step from automation to autonomisation. Apart from the technical and legal challenges, the primary question concerns the customer segment in which an economic advantage will become apparent.

Autonomy in the Controlled Row Farming system

In 2020, AMAZONEN-WERKE started new long-term field trials together with its subsidiary SCHMOTZER Hacktechnik and its partner Agravis. The Controlled Row Farming (CRF) trials at the new AMAZONE test centre in Wambergen, in the direct vicinity of the production site and main plant in Hasbergen-Gaste, will contribute important findings to new crop production methods in the coming years. With a fixed row width of 50 cm in all crops, the sensitive inputs of fertiliser and plant protection are reduced through precise placement. An additional goal is to increase biodiversity in the field and to keep the economic success of the farm at least constant. The first harvest results confirm a constant yield, also in cereals in a double row with a spacing of 50 cm. The results can also be found at www.controlled-row-farming.de.

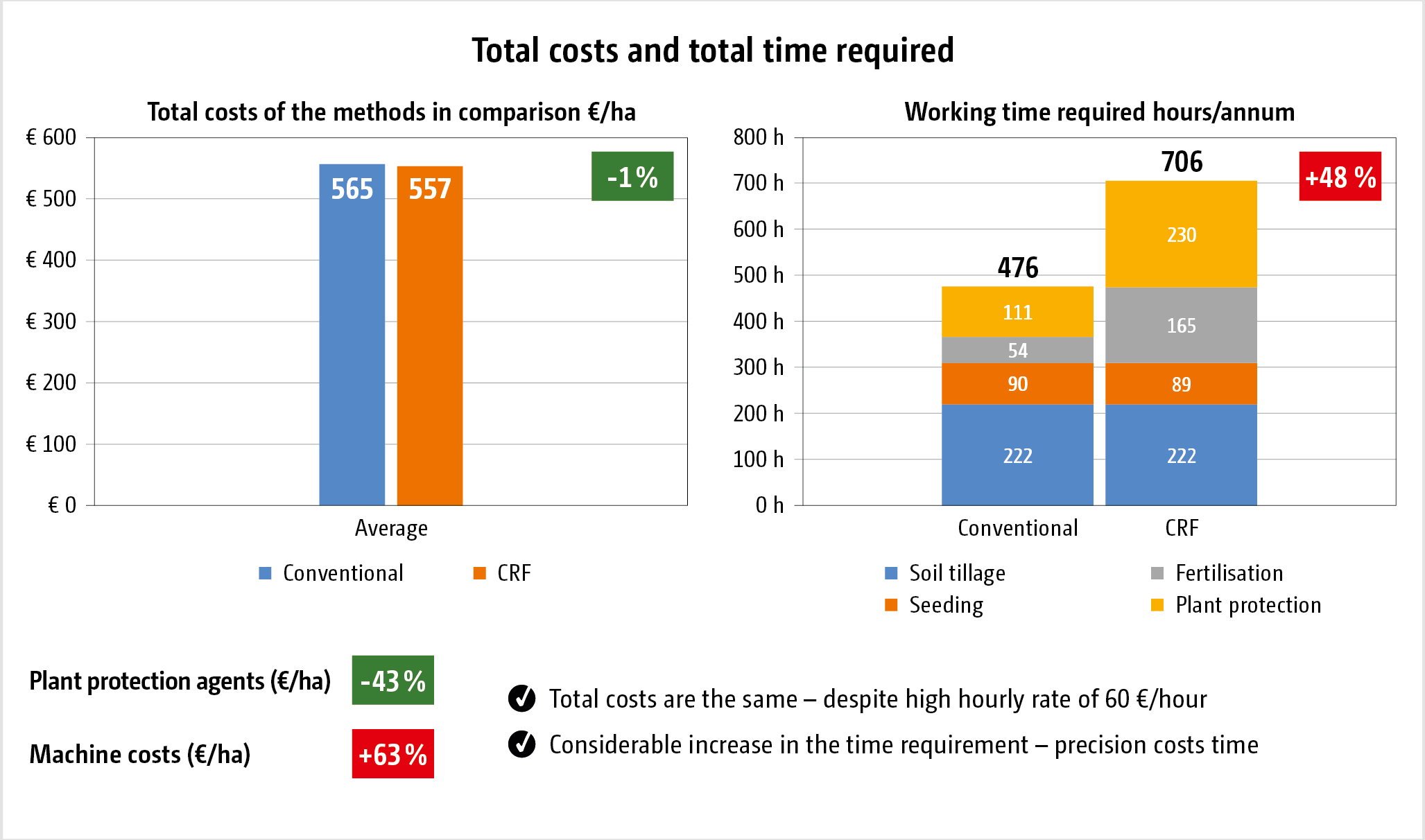

In an illustrative economic analysis of the CRF system for a farm with 300 ha, it becomes clear that the reduced costs for the inputs are offset by the increased costs for labour.

Apart from the purely economic consideration, the additional work time required in the main season is a critical point: 476 hours/annum are required for fertilisation and plant protection in conventional arable farming compared with 706 hours/annum (+ 48 %) in the CRF system. In times of a shortage of skilled labour, this factor is critical in the short term. Autonomous agricultural machinery in the CRF system could undertake the labour-intensive tasks for the farmer in the medium to long term. The clear structure in the track guidance and cultivation system suits the robotic systems in any case.

Today, the CRF system is operated with conventional RTK-guided tractors, intelligent connected implements and an attentive driver. It is easy to imagine the use of autonomous field robots for this in the future. Every step of the process would be closely monitored. Slower speeds with smaller working widths and completion of the tasks with even more precision are then also conceivable. Ultimately, the farm manager will have to spend less time monitoring standardised work processes and be able concentrate on other tasks.

Autonomous agricultural machinery, precision technologies and Controlled Row Farming